Student Name: Muhammad Rzi Abbas

Research Topic: A Unified Framework for Design and Development of Cobotic Manipulators

Supervisor: Dr. Muhammad Ahsan

Current Progress: In-process

Description

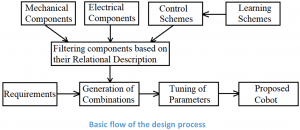

In the presence of wealth of literature/expertise on designing/developing individual subsystems of cobots (e.g. control mechanics, electronics etc.), one can explore optimal cobot system for given set(s) of applications, based on efficient combinations and re-combinations of these subsystem blocks. Efficient connection of subsystem blocks will depend on compatible input/output ports (relational description) of interacting blocks. At this stage, one of the most difficult problem will be to establish a parameterizable description of subsystem that enables rapid validation of combination (based on defined criterion e.g. stability, manipulability etc.) as well as efficient evaluation of the performance (e.g. repeatability, interaction safety, power consumption etc.) of resulting super system. Tuning of parameters of involved subsystems shall ensure that intrinsic as well as extrinsic requirements are met. Range of AI search algorithms shall be employed for searching the parameter design space. Figure 1 depicts the overall flow of the procedure.

In the presence of wealth of literature/expertise on designing/developing individual subsystems of cobots (e.g. control mechanics, electronics etc.), one can explore optimal cobot system for given set(s) of applications, based on efficient combinations and re-combinations of these subsystem blocks. Efficient connection of subsystem blocks will depend on compatible input/output ports (relational description) of interacting blocks. At this stage, one of the most difficult problem will be to establish a parameterizable description of subsystem that enables rapid validation of combination (based on defined criterion e.g. stability, manipulability etc.) as well as efficient evaluation of the performance (e.g. repeatability, interaction safety, power consumption etc.) of resulting super system. Tuning of parameters of involved subsystems shall ensure that intrinsic as well as extrinsic requirements are met. Range of AI search algorithms shall be employed for searching the parameter design space. Figure 1 depicts the overall flow of the procedure.

The developed framework shall also guide the developer/researcher to approximate the extent to which an already installed industrial manipulator may be toned into a cobotic manipulator. Major distinctions between a cobot and an industrial manipulator, being considered here, are their inertias, stiffness and methods of feedback.

The developed framework shall also guide the developer/researcher to approximate the extent to which an already installed industrial manipulator may be toned into a cobotic manipulator. Major distinctions between a cobot and an industrial manipulator, being considered here, are their inertias, stiffness and methods of feedback. The proposed framework will help in suggesting the minimum possible modifications required for an industrial manipulator, by possibly projecting its apparent inertia and stiffness close to that of an equivalent cobot.

The proposed framework will help in suggesting the minimum possible modifications required for an industrial manipulator, by possibly projecting its apparent inertia and stiffness close to that of an equivalent cobot.

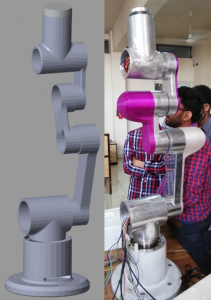

Concurrent to the development of the framework, an industrial-grade robotic manipulator is also being developed by utilizing the knowledge gained from the development of the framework.